When it is about conducting a life cycle evaluation for packaging, it has some steps and tips. Here are a few useful hacks that could help you out is the assessment procedure.

- Reduce Packaging Material with the Fastest ROI

The first vehemently important element is to reduce the packaging material and remain it at the lowest hanging fruit. Also, it can provide the fastest ROI. Designing minimal packaging that can protect and attract your customers and the product could be difficult. Moreover, every product’s packaging engineer thinks these two necessary points. Another component is to exhibit the brands’ message, name, and logo. Well, to keep the packaging sustainable and biodegradable, you need to eliminate some primary components. You need to reduce polybags, instruction booklets, and printed labels. Well, some digital printing is not harmful. Thus, it depends on which technology you have you want to use.

- Ignore the Perception that Every Plastic is Bad

Producers, manufacturers, industries, and people are assuming that every kind of plastic is bad. Well, this is just a myth about plastic. Even science has proved that every plastic is not bad and is better than some other packaging materials like glass. Some companies and customers are thinking that plastic is less expensive and having low weight, that is why people consider it as less harmful. Well, this is true, it is not as dangerous for the people, air, environment, nature, marine life, and animals. For packing, you can use bubble plastic, polymers, and some other kind of plastic. Even cellulose packaging is one of the best options for food packaging.

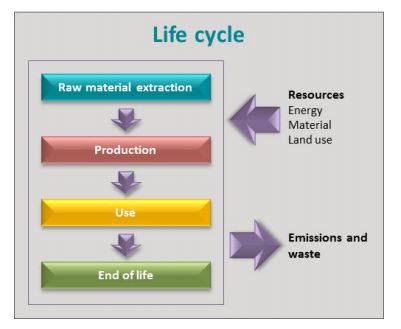

- Keep your Concepts Wide while Conduction an LCA

Many manufactures do a mistake and that is focusing on one element only. Well, while planning a packaging methodology, you need to keep your eyes on primary, secondary, paramount necessary, less important, and tertiary elements. This can mislead your entire procedure and packaging methodology. Therefore, every small and minor component is necessary for the making of packaging. Moreover, do not just focus on one LCA indicator like greenhouse gas GHG. While taking measurements for GHG and LCA, be attentive, some misleading measuring techniques can ruin your entire procedure.

- Rigid and Flexible Packaging Sketches

When you are already in the business of packaging or you are selling some kind of products and you need packaging boxes, you might have used flexible and rigid materials. Sometimes you only use flexible or rigid. However, in a few cases, you need to switch from flexible to rigid. You will have to shift the structures. Well, the reductions will be slow and dramatic in LCA impacts. The flexible packaging is usually unable to recycle. It has typical municipal infrastructure. However, the procedure will take some dramatized twists. It has primary packing that has supplemented with additional savings in the rigid packaging conversion.

- Understanding of the Tradeoffs

Packaging has one common concept of reducing the environmental impact these days. While deciding the packaging material and procedure, you cannot make or ignore the functional impacts and cost requirements. Therefore, it is vehemently necessary to understand the tradeoffs. While making and choosing LCA tools, you should allow your team and production department to understand the LCAs and tradeoff concepts. Thus, you can reduce the extra cost and make your packaging procedure economical. When you have these necessary concepts, you will know the sustainability and importance of the packaging.

- LCA s Cost and Time

Some production departments have a myth about LCA. They are assuming that they are expensive and will consume more time. Well, it could be true. But most chances are pointing out towards some other elements.